Container handling has never been more accurate! Visy TopView, the leading spreader OCR system, transforms operations by automatically identifying container IDs with precision. The compact camera system is compatible with all types of equipment. Whether using in container cranes or smaller CHE, it seamlessly integrates with single, tandem, twin, and quad spreaders, making any spreader a smart device.

Container Handling Gets Smarter

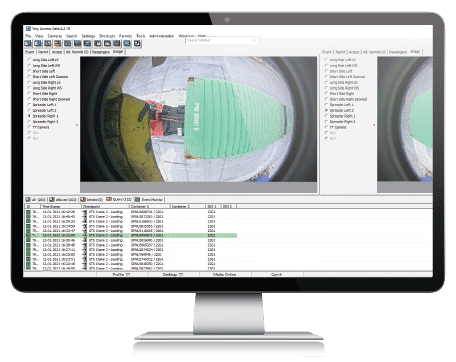

Visy TopView – an OCR camera system – is a tool for improving operational accuracy by automatically checking container IDs and capturing images of container roofs during handling processes. TopView utilizes intelligent AI-based container OCR software that processes the captured images on recognition PC and validates them to achieve high recognition rate. The solution is integrated with relevant systems, such as PDS and TOS, to enhance existing automation processes through data collection and sharing.

With instant data sharing, operators gain transparency and ensure that every lift is recorded and saved in the database.

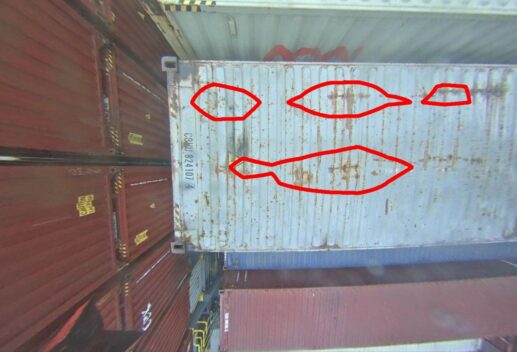

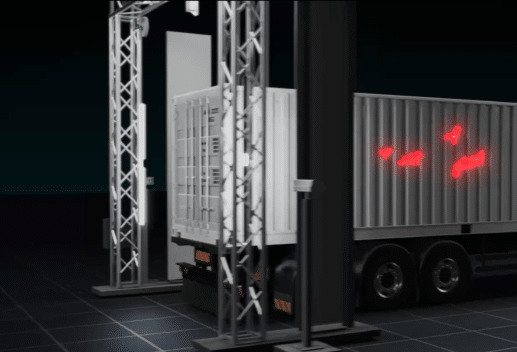

In STS, RTG, and RMG solutions, Visy ADDS can be deployed on TopView to automatically detect damage on containers arriving from outside the terminal for liability purposes giving you the proof that they were already damaged when arriving. Visy TopView gives you access to the most common side for hole damages – the roof.

The system architecture is always designed according to the needs and requirements of the project and the CHE in question by experienced professionals. All imaging equipment is directly installed on the spreaders, such as cameras, illuminators and a device cabinet. The design has been structured in a way that it allows high flexibility regarding requirements from all perspectives, e.g. IT, hardware and process, leading to best solution from functionality and costs to every customer.

Visy has extensive experience on installing Visy TopView to different equipment that no other vendor can match – from container cranes to top loaders, and even automatic RTGs – machines with very different workflows and operational requirements. What is common between all of them, is that TopView always creates recognizable benefits for the customer and their process.